K-Grip Clamps for Klip-lok, Saflok, Domitec, etc.

The design utilizes multiple inserts (see list below) in order to accommodate a variety of bulb snap together profiles.

The K-Grip-Clamps, made of Aluminium, are suitable for all roofing materials except copper.

The K-Grip-Clamp and K-Grip-Mini are not on stock available but can be shipped from S-5!, USA, after costumer request – even in small quantities and in short time with air freight. Please call us for quote.

There are 2 options of K-Grip-Clamps:

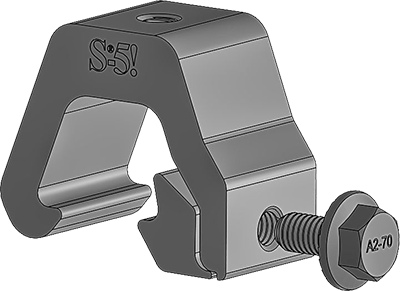

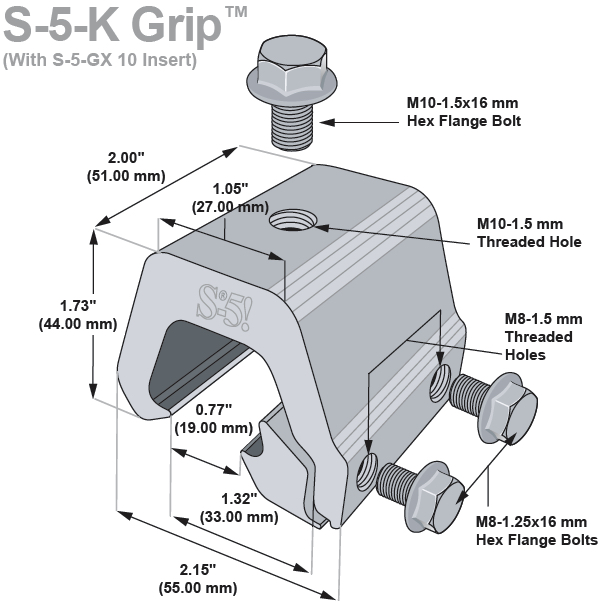

The K-Grip-Clamp with two M8-bolts sideways, one centered M8 thread on top and M8 stainless steel bolt, is used for heavy demands and in theS-5! ColorGard® snow retention. K-Grip-Clamp is packed with 20 pieces per box.

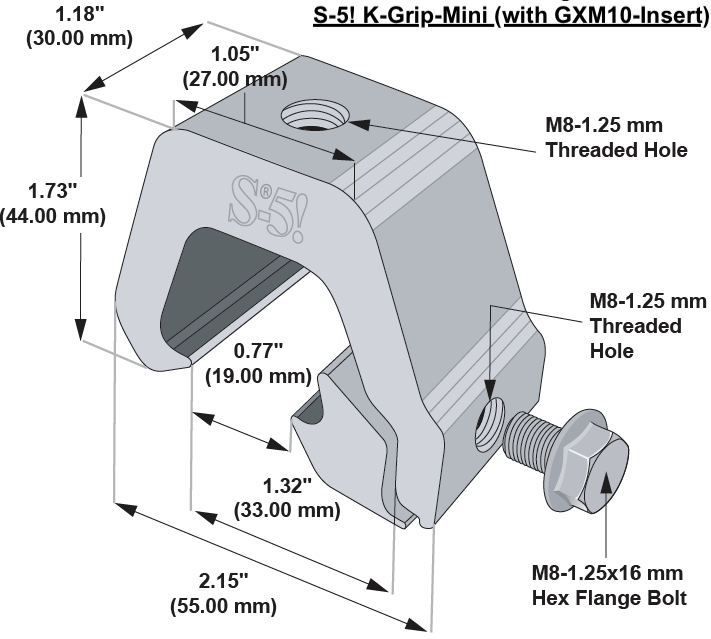

The K-Grip-Mini with one M8-bolt sideways and a M8 thread on top is utilized in various instances when multiple clamps are required for the attachment of rigid objects to the seams, e.g. rail systems for solar installations, S-5-PVKIT® 2.0, rail systems, walkways, signs, satellite dishes, cable trays, pipe and cable laying, etc.. (not suitable for snow retention). K-Grip-Mini is packed 40 pieces per box.

For mounting rails with screw channels underside or beside, the K-Grip-Mini can be easily and inexpensively combined with different adapter plates.

The S-5!® Mini clamps with M8 thread will be supplied without M8x16 stainless steel screws. These ( A2-70, full thread, hexagon with flange and locking serrations, DIN 6921 / EN 1665) can be ordered separately if required. PU: 100 pieces per box.

The set screws of the S-5!® clamps have a Torx-30 female thread now. The S-5!® set screws are available in two lengths: 13mm (for E + B clamps) and 23mm (for S, Z + N clamps).

An S-5!® mounting bit Torx-30 (for electric screwdrivers with torque control) for mounting the S-5! set screws is included in each clamp box.

The tightening forces remain unchanged.

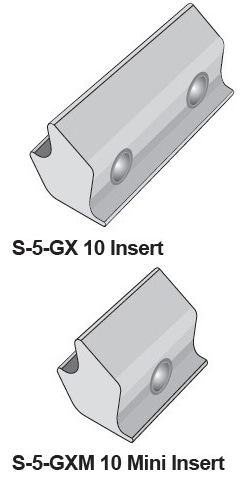

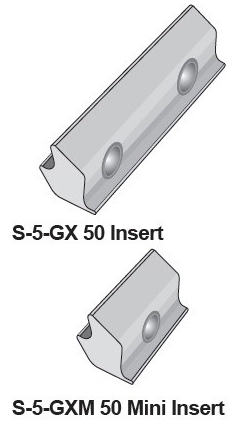

Four different inserts are packed and sold separately:

Each insert has a unique shape that allows for a tight fit at the profile and provides increased holding strength.

- GX10- or GX50- Inserts for the K-Grip-Clamp (100 pieces per box).

- GXM10- or GXM50- Inserts for the K-Grip-Mini (200 pieces per box).

Profiles and the Insert Options:

With Insert S-5-GX10 or S-5-GXM10:

- Domico: Domitec

- LYSAGHT KLIP-LOK® 406

- McElroy Metal Mirage

- AEP Span Klip-Rib®

- Metal Sales Clip-Loc

- SpeedDeck® SpeedDeck®

- Safintra Saflok 410

- Safintra Saflok 700

- or similar profiles.

With Insert S-5-GX50 or S-5-GXM50:

- Lysaght: Klip-lok Classic 700

- Lysaght: Klip-lok 700 Hi-Strength

- Stramit: Speed Deck Ultra

- Filders: KingKlip 700

- or similar profiles.

If you have a profile not listed here, please contact us.

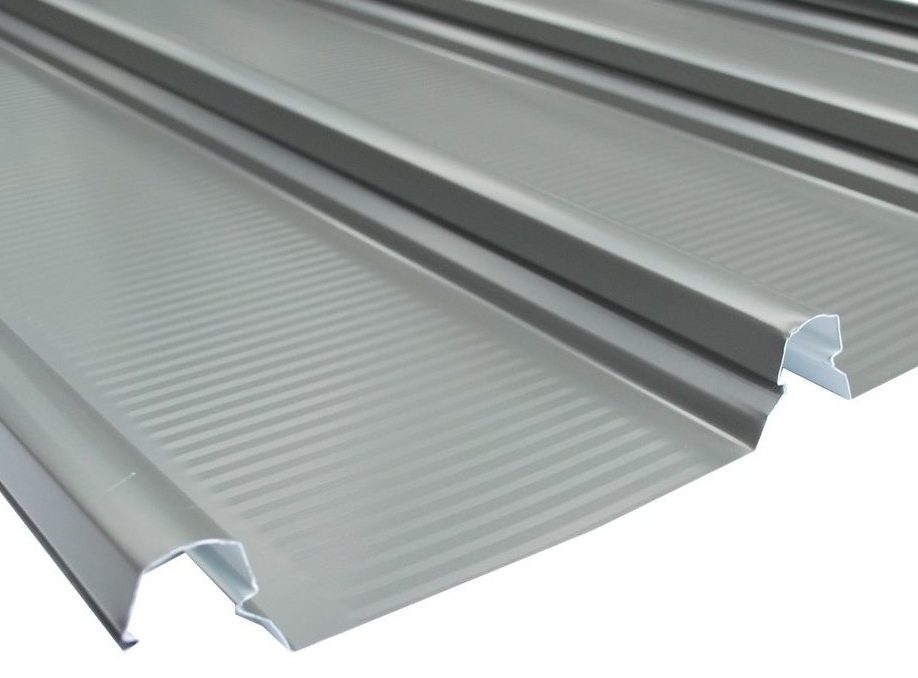

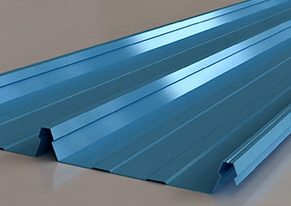

Profile – Examples:

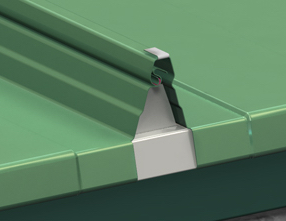

Examples of Applications:

S-5! PV-Kit 2.0 and rail systems installed with S-5! K-Grip-Mini with GXM10-Insert on Domitec profiles.

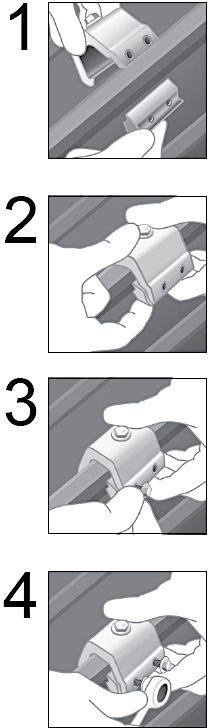

Install S-5! K-Grip Clamps:

The S-5-K Grip utilizes multiple inserts in order to accommodate a variety of bulb snap-together profiles. Each insert has a unique shape that allows for a tight fit and provides increased holding strength over other attachment options. The appropriate seam profiles for each insert option are listed above and on the back of the installation instructions. The head of the clamp’s flanged bolts control the amount of compression, which reduces the possibility of over-compressing the seam, and makes installation a snap!

1. Position clamp insert at desired location along the rib, just under the fold of the rib. Mount the clamps only on the overlapping ribs or seams of the roofing. And don’t fix the clamps on or beside the clips because the thermal elongation of the panels may not be hindered!

2. Roll the clamp into position over the seam and clamp insert piece. Position the clamp so that it is centered over the clamp insert with approximately 2mm of insert overhang on each side of the clamp.

3. Partially thread the two flanged bolts into the base of the S-5-K Grip by hand, or the single flanged bolt into the base of the S-5-K Grip Mini. The bolts should engage the divots in each end of the S-5-K Grip insert and in the center of the S-5-K Grip Mini insert.

4. Tighten the bolts at the base of the S-5-K Grip using a ratchet or screw gun with a 13mm hex. For optimal holding strength, bolts should be tensioned to 23 Nm (200 inch pounds).

5. For critical attachment applications utilizing an M8 X 16 mm Hex Flange Bolt, tighten it with 18Nm.

When planning and installing with the S-5!® clamps and our other products, please always observe the following general points:

-

The respective product installation instructions from us and our producer must always be observed (available in all boxes, on our homepage www.rooftech.de or please send us an inquiry). During the entire installation period, it must be ensured that at least one copy of the relevant installation instructions is available on the construction site to all those involved in the installation and that it is strictly observed during installation.

-

Installation with our products should only be carried out by specialists and specialist companies with qualifications for the respective installation and with experience in working on roofs. During installation, the warranties of all trades involved and of the roof as well as the respective regulations for work on roofs must be observed (e.g. the use of fall protection, scaffolding with safety gear from an eaves height of 3 m, accident prevention, insurance, etc.). The presence of two persons is mandatory for the entire assembly process in order to be able to guarantee rapid assistance in the event of an accident.

-

The respective installation instructions do not release the contractor from the obligation to clarify the possible uses and application of our products, also in combination with the other materials and products used, on the individual property in advance. The user and/or installer also bears the responsibility not only for the professional installation, but also for the roof on which he is mounted. If you are missing important and necessary information, please request it from us.

-

In the case of non-observance of our installation instructions, or assembly of our products with components of competitor and in the event of the use and combination offurther components which were not purchased from us, we shall not accept any liability for any resulting defects and damage. The warranty is excluded in this respect.

-

The individual types of the S-5! clamps are designed as described for the respective seam and profile types. However, new variants of standing seams and profiles come onto the market regularly. To avoid possible damage, it is important to check the suitability of the clamps for the intended metal roof before installation.

-

Responsible for the stability of a building structure is the building owner or the owner or operator. The installer of the system is responsible not only for the system but also for the roof on which the system is installed. Whoever installs a system on an existing roof without having checked the stability beforehand, violates existing law! For critical installations, inquire for specific test data of ultimate tensile load on specific panel materials and seam types. The sufficient holding force of the roofing to the supporting orsubstructure must always be ensured. The sufficient holding force of the roofing on the supporting or substructure must always be guaranteed. Proof must be provided by thecustomer or installer. In cases of doubt, a structural engineer must be consulted to determine the loads and its effects.

-

The maximum static loads for the individual products and the roof must always be observed. With very few exceptions, the load-bearing capacity of each individual S-5!® clamp is stronger than the load-bearing capacity of the roof panels or the profiled sheets and their attachment to the supporting structure. This applies not only to thenormal clamps but also to the S-5!® Mini clamps. Therefore, the weak points are usually not the clamps, but the roofing and its fastening.

-

Fastening a system increases the roof’s inherent load. The forces from the permanent loads increase and the load-bearing capacity of the roof must be ensured. Please make sure that the loads coming into the clamp will be taken by the structure of the roof. Assumption is that the determination has been made that the roof to which the S-5! clamps will be attached is structurally adequate. Any loads imposed on the S-5! clamps will be transferred to the panels. Panel seams must have sufficient flexural strength to carry these loads. Panels must also be adequately attached to the building structure, and the structure must be sufficient to carry these loads. In particular,the snow and wind loads, the additional loads from the installations attached to the clamps, as well as the increased loads in the edge and corner areas of the roof construction must be considered.

-

A sufficient number of clamps must be provided. For statically relevant clamps, a distance of at least 500mm from the end of the standing seam profile must be maintained. RoofTech and the makers of the S-5! clamps make no representations with respect to these variables. It is the responsibility of the user to verify this information or seek assistance from a qualified design professional or structural engineer, if necessary.

-

In the case of handcrafted metal roofing on wooden formwork, the edge and corner areas should not be covered with PV-modules due to the limited load-bearing capacityof the roofing and the adhesives. In the central area, the skipping of seams is usually not possible. Therefore, we recommend to install clamps on each seam. The installation of PV systems represents a punctual load entry; therefore, we recommend reduced clip distances and screwed clips. The mounting and fastening of the clamp should be carried out between the clips to achieve an optimal load sharing.

-

The thermally induced change in length of the roofing must not be hindered! With some roofs made of profiled sheets (e.g. with round bulb seams, snap folded seams, RibRoof seams, etc.), it must be ensured that the clamps in the sliding area of the sheets are not mounted on or next to the holders of the roofing. In the case of double standing seam roofing, the S-5!® E and B clamps can, under certain circumstances, hinder the thermally induced length change of the sheet if, despite the high clamping point of the S-5!® E and B clamps, the foot of a sliding clip extends into the clamping area of the clamp. In this case, the S-5!® E and B clamps should be placed at a distance of 25 mm from the sliding clips.

-

Through a mounting system, its fastening, any existing intermediate construction and when mounting rigid objects on the clamps, such as rails, pipes, cable ducts, walkways, etc., these must be separated at regular intervals (after a maximum of 3 meters in the case of standing seam roofs) in order to limit deformations due to thermally induced elongation of the materials (in the longitudinal and transverse direction). When installing modules with the S-5! PV-Kit 2.0 in a row from the eaves to theridge, a separation is necessary after a maximum of 10 modules to limit deformations due to thermally induced changes in length of the installed materials.

-

Please observe the country-specific legal and official regulations for snow retention. Depending on the location of the building, height of the terrain above sea level, roofshape, roof pitch, type of metal roof and the respective holding strength of the S-5! clamps, the suitable snow guard systems must be professionally calculated and designed.

-

The material properties of the respective metals, the combination with each other as well as the installation instructions and regulations of all manufacturers involved (including those of the metal roof) must be observed. If technical details are not described separately, this does not release the company carrying out the work from its obligation to check the individual case and clarify the correct technical facts beforehand.

-

S-5!® Warning: The S-5! clamp is a handy gadget for a great many uses, but will not perform miracles. Please use the products responsibly! Visit the website of S-5! (www.s-5.com) or RoofTech GmbH (www.rooftech.de) for available load test results. The user and/or installer of these parts is responsible for all necessary engineering and design to ensure the S-5! clamps have been properly spaced and configured.

-

Notice to S-5! users: Due to the many variables involved with specific panel products, climates, snow melt phenomena, and job particulars, the manufacturer cannot and does not express any opinions as to the suitability of any S-5! assembly for any specific application and assumes no liability with respect thereto. S-5! products are tested for ultimate holding strength on various profile types and materials.

-

The user and/or installer of all our products is responsible for all necessary engineering and design to ensure that the S-5! clamps and other products has been properly spaced and configured. It is the responsibility of the user to verify this information, or seek assistance from a qualified design professional or stress analyst, if necessary. RoofTech, the makers and distributor of S-5! clamps make no representations with respect to these variables.

-

For critical installations, inquire for specific test data of ultimate tensile load on specific panel materials and seam types. When tabled values are used, screw tensions should be verified and factors of safety should be used as appropriate. RoofTech and the manufacturer expresses no opinions as to the suitability of the S-5!products for any specific application or project condition.

-

S-5! Clamps are not suitable as fall protection applications and personal fall restraint. The S-5! clamps may only be used for this purpose in a certified and approved fall protection system. The respective system provider is responsible for this and must provide proof of this.

-

When installing a PV system, the grounding / equipotential bonding must be carried out according to the national and locally applicable standards and directives (in Germany, among others, according to VDE 0100). The recommendations and installation instructions of the module manufacturers must also be observed. The commissioning of a PV system and the connection to the power grid must be carried out by an authorized electrician or by the grid operator and is its responsibility.

-

It must be ensured by the planner and the specialist company responsible for the installation that the planning and installation are carried out strictly in accordance with the national and site-specific building regulations, occupational safety and accident prevention regulations, standards and environmental protection regulations. Every person and company who plans and installs with our products is obliged to inform himself independently about all rules and regulations for technically correct planning and installation and to observe them. This also includes obtaining the current status of the necessary rules and regulations.

-

RoofTech GmbH, S-5!® – Metal Roof Innovations Ltd. and the other manufacturers of our product range recommend in principle that the planned installation, PV system, snow guard system, etc. should be verified by a qualified professional who is responsible for the snow and wind loads, the additional loads from the installations attached to the clamps, the statics and assembly as well as the planning and construction of and on metal roofs.

-

The information provided in our documents and on our homepage and the drawings and photos shown are intended to clarify individual details and are intended as recommendations only. RoofTech GmbH and our manufacturers accept no liability for this. Please also note the information and copyright notices of our manufacturers.

-

The suitability of our products for the intended use is the responsibility of the planner and user. If technical details are not described separately, this does not release the company carrying out the work from checking the individual case and clarifying the correct technical facts in advance. RoofTech GmbH, S-5!® – Metal Roof InnovationsLtd. and the other manufacturers of the products we sell do not accept any responsibility for installation, suitability and applications, nor any further liability.

Download (pdf): General Notes for Installations with S-5! Clamps

The installation instructions and more information to download under “Information”. We would also be pleased to send you the respective installation instructions and the requested information. We look forward to your message or call.

All load test results, CAD details, metallurgical compatibilities, specifications, S-5! Terms of Use and additional information are available on the homepage of S-5!: www.s-5.com.

S-5!® products are protected by multiple U.S. patents. European patents are also applied for and pending under the Patent Cooperation Treaty with divisional filing rights retained.

We assume no liability for errors on our website and in our documents. Pictures and drawings in our documents and webpages serve to clarify individual detail designs and are only recommendations. They can represent development stages, which are not available in such a way. The contents, logos, photos and graphics may only be used or passed on after consultation with RoofTech GmbH. The content and works provided on these Web pages are governed by the copyright laws of Germany. Duplication, processing, distribution, or any form of commercialization of such material beyond the scope of the copyright law shall require the prior written consent of its respective author or creator.

The linking of external websites to the RoofTech website is only permitted with the consent of RoofTech GmbH and if no rights of RoofTech GmbH are violated.

The business relationship is subject to German law, excluding the UN Convention on Contracts for the International Sale of Goods (CISG). Our General Terms and Conditions of Business (GTC) apply, which we will be happy to provide you with at any time (direct link to our RoofTech GTC).

As a matter of principle, sales are only made to companies (commercial users, § 14 BGB – German Civil Code).

No liability for printing errors. Technical changes subject to modification.

© Copyright RoofTech GmbH, 2024. All rights reserved.

Peter Strobel

Peter Strobel