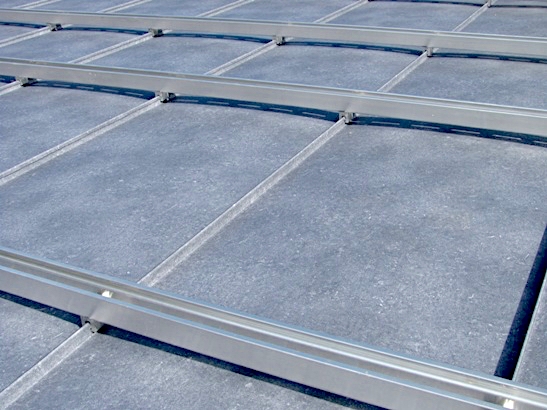

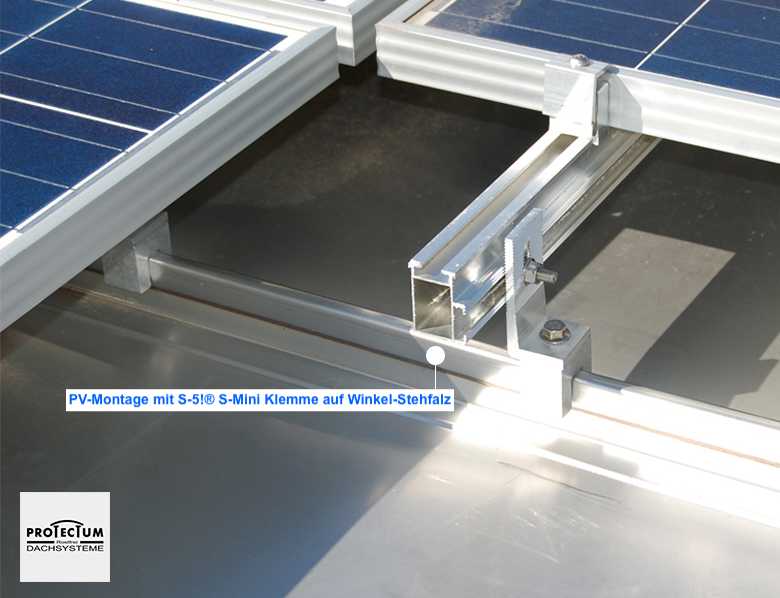

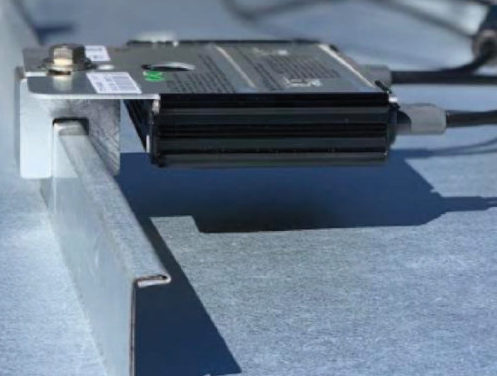

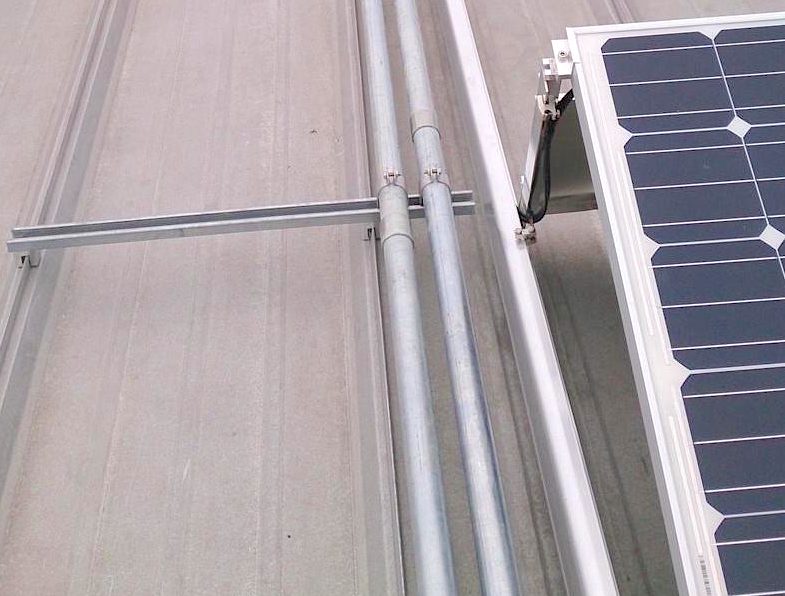

PV systems can be mounted with rail systems or directly with the S-5-PVKIT® 2.0 on the S-5!® Clamps. In contrast to plagiarism and conventional seam clamps, only the original S-5!® Clamps are all multiple tested on different materials and profiles by a third-party accredited US-lab. They offer highest quality and high load capacities in all load directions.

Many well-known international mounting system manufacturers and dealers have been using the original S-5!® Clamps with their systems successfully worldwide for years. Installers appreciate the high holding strength and the simple, fast and professional installation. The S-5!® Clamp is selected by the type of seam or profile of the metal roof.

Please note in general:

The following suggestions assume that determination has been made that the roof to which the S-5! clamps will be attached is structurally adequate. Any loads imposed on the S-5! clamps will be transferred to the panels. Panel seams must have sufficient flexural strength to carry these loads. Panels must also be adequately attached to the building structure, and the structure must be sufficient to carry these loads. The makers of S-5! clamps make no representations with respect to these variables. It is the responsibility of the user to verify this information, or seek assistance from a qualified design professional, if necessary.

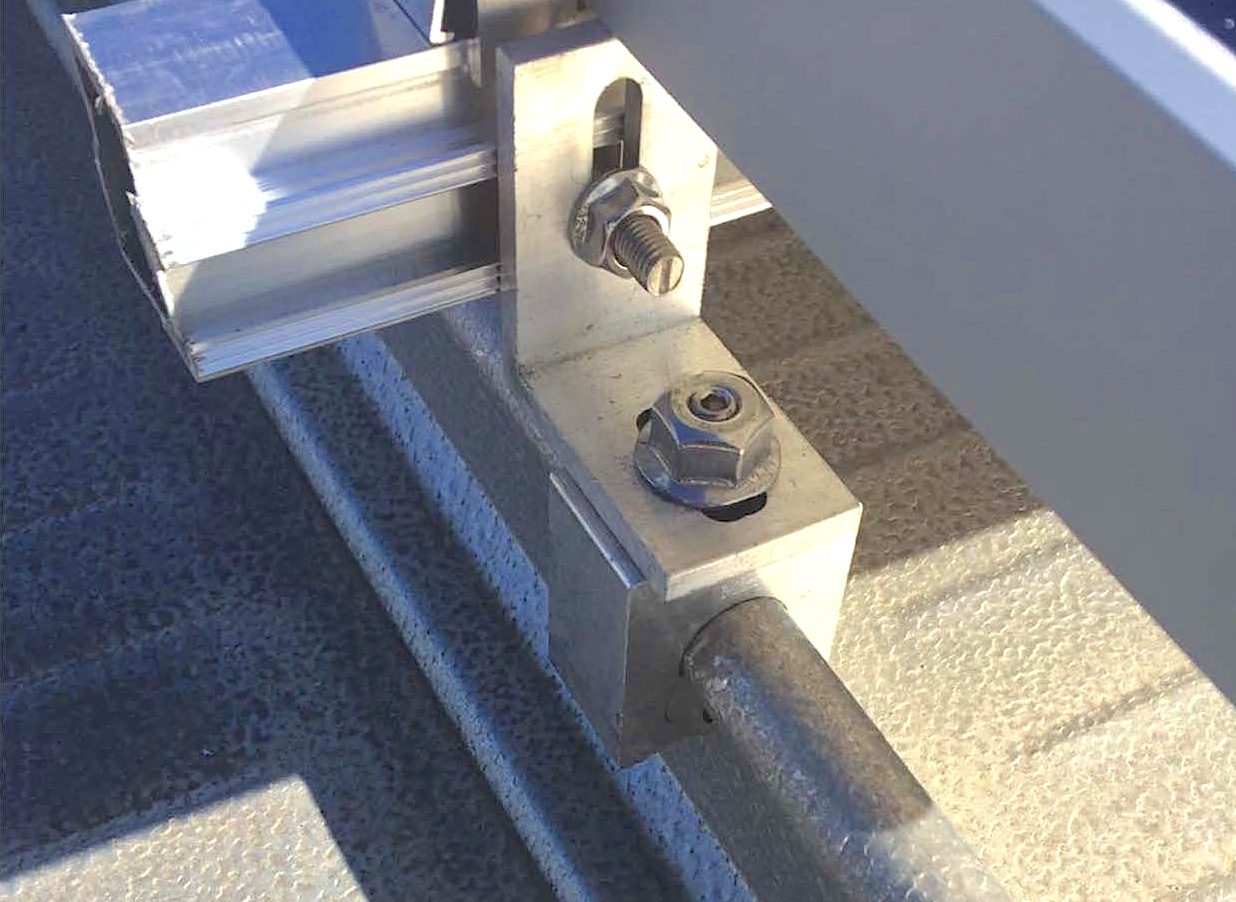

The key to frequency and spacing of attachment points for PV is to distribute loads to the metal standing seam panels in a manner that is consistent with the intended distribution of loads from the roof panels into the building structure. With very few exceptions, the attachment of a single S-5! clamp (even the “Mini”) to the seam will be stronger than a single point of attachment of the seam to the building structure. Hence the “weak link” is not the S-5! clamp, but the attachment clips that hold the metal panels to the building structure, or the beam strength of the roof panel seam, itself.

The most conservative approach to the spacing/frequency of PV attachment to the roof is to determine the spacing/frequency of the roof’s attachment to the building structure; then duplicate it at minimum. Determining panel attachment spacing in one axis is very simple: Standing seam panels’ attachment will be made using concealed hold-down clips within the seam area of the panel. So, in that axis, the clip spacing is the same as the seam spacing. The location of the clips along the seam (in the other axis) can be determined by a) consultation with the roof system manufacturer or installer, b) checking from the underside or, c) close examination from the topside along the seam. There will usually be a slight, but detectable, deformation of the seam at the clip location visible from the roof’s topside. Many standing seam roofing systems are installed on “pre-engineered steel” buildings. The attachment spacing in that industry is typically 5’-0” and is readily apparent by inspecting the structural purlins to which the panel clips are attached from the roof underside (interior of the building).

If the panel clips are spaced, for instance, 5′-0″ on center along the seam, then use the 5′-0″ dimension as a maximum spacing for the S-5! clamps. (S-5! clamps may also be spaced at closer centers, but not wider.) When modules are direct attached (without racking) in the landscape orientation, this spacing dimension is dictated by the smallest dimension of the PV frame. Using the roof panel clip spacing as a maximum spacing template for S-5! clamps is a sound practice, whether the PV modules are attached direct to S-5!, or to a racking system, which is in turn attached to the S-5! (and panel seams). To evenly distribute loads, it is also necessary that each seam be involved in the finished assembly. Thus, every time a seam is traversed, it should be attached. Such an attachment scheme should evenly distribute wind loads into the building structure through the panels and their attachment, as was intended in the original roof construction assembly.

Please note these are only suggestions. Wind dynamics are complex, and S-5! advises review of the planned PV frame attachment design by a qualified professional who understands wind effects and metal roof design and construction. In certain solar installations, a design professional may determine that seams can be skipped as points of attachment, but this determination must be made on a job-specific basis.

The respective installation instructions must always be observed. However, the respective installation instructions do not release the executing company from the obligation to clarify in advance the possible uses and applications of our products, also in connection with the other materials used, on the individual object. RoofTech GmbH and S-5!® – Metal Roof Innovations Ltd. do not assume any responsibility for assembly and applications.

The installation instructions and more information to download under “Information”. Load test results, CAD details, metallurgical compatibilities, specifications, S-5! Terms of Use and additional information are available on the homepage of S-5!: www.s-5.com.

We would also be pleased to send you the respective installation instructions and the requested information. We look forward to your message or call.

We assume no liability for errors on our website and in our documents. Pictures and drawings in our documents and webpages serve to clarify individual detail designs and are only recommendations. They can represent development stages, which are not available in such a way. The contents, logos, photos and graphics may only be used or passed on after consultation with RoofTech GmbH. The content and works provided on these Web pages are governed by the copyright laws of Germany. Duplication, processing, distribution, or any form of commercialization of such material beyond the scope of the copyright law shall require the prior written consent of its respective author or creator.

The business relationship is subject to German law, excluding the UN Convention on Contracts for the International Sale of Goods (CISG). Our General Terms and Conditions of Business (GTC) apply, which we will be happy to provide you with at any time (direct link to our RoofTech GTC). The linking of external websites to the RoofTech website is only permitted with the consent of RoofTech GmbH and if no rights of RoofTech GmbH are violated.

No liability for printing errors. Technical changes subject to modification.

© 2020 Copyright RoofTech GmbH and S-5!® – Metal Roof Innovations Ltd.. All rights reserved.

Peter Strobel

Peter Strobel