Multi-Trapezoidal-Bracket MTH

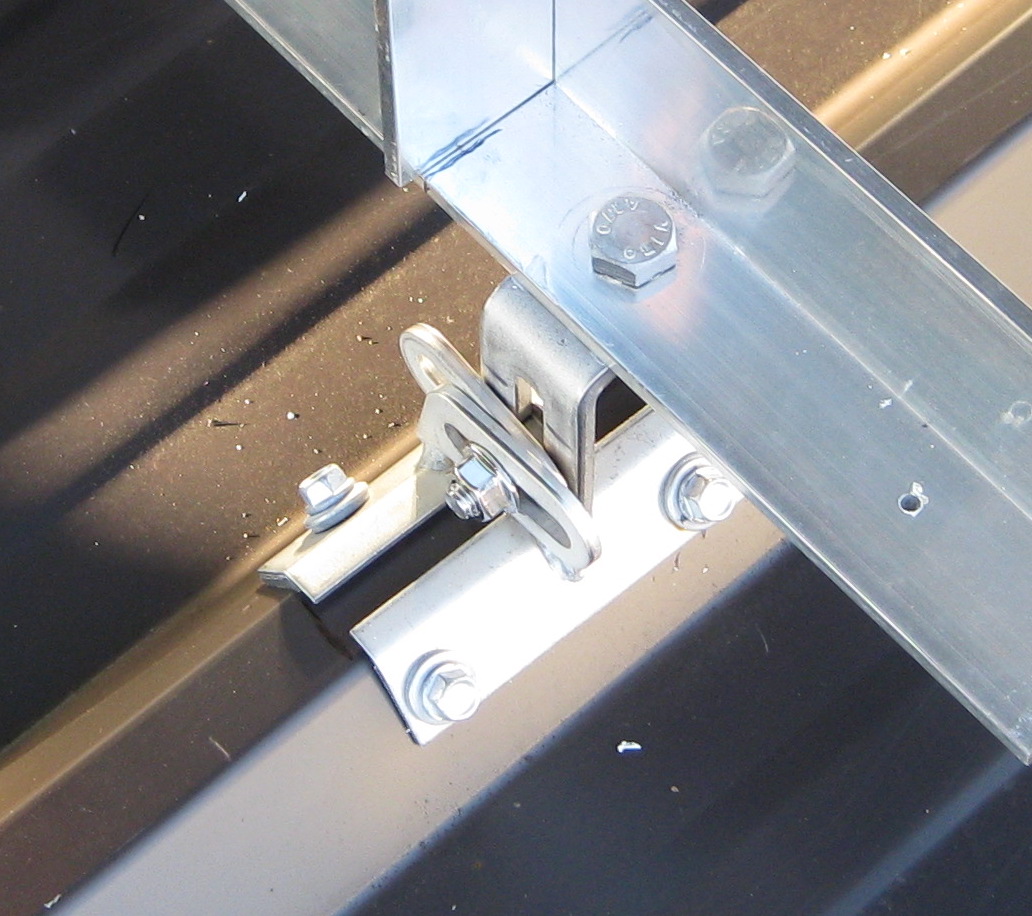

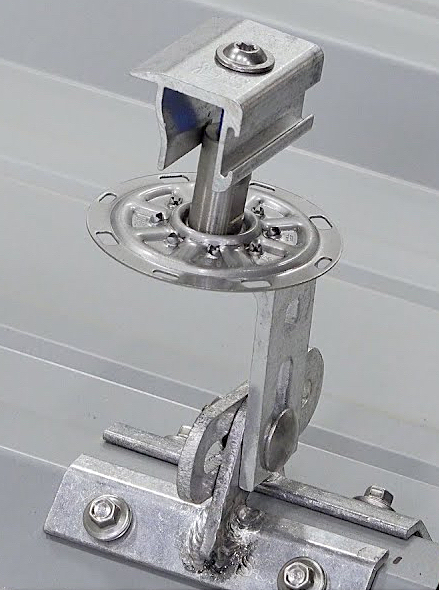

The adjustable Multi-Trapezoidal Bracket MTH, made of 5 mm stainless steel, with mounting bracket and self-adhesive sealing strips, can be flexibly adapted and mounted on many shapes of trapezoidal sheet metal and sandwich profiles with an upper cord width up to max. 43mm (according the approval).

Official tested and approved by the DIBt (German Center of Competence for Civil Engineering – Authority of the German Government): DIBt. No. Z-14.4-706.

Multi-Trapezoidal Bracket MTH with self-adhesive sealing strips and an a height-adjustable angle mounting bracket (56 and 65mm side length) with M11 slotted holes.

Material: 5mm stainless steel A2. For flexible mounting on many shapes of trapezoidal sheet metal and sandwich profiles up to 43mm top chord width (according the DIBt approval).

Packed with 50 pieces per box.

Advantages:

• Flexible adaptation to many trapezoidal sheet shapes

• Height-adjustable angle mounting bracket – thus less tensions on the rails

• Mounting fixation with self-adhesive sealing strips

• Optimum tightness due to EPDM sealing strips

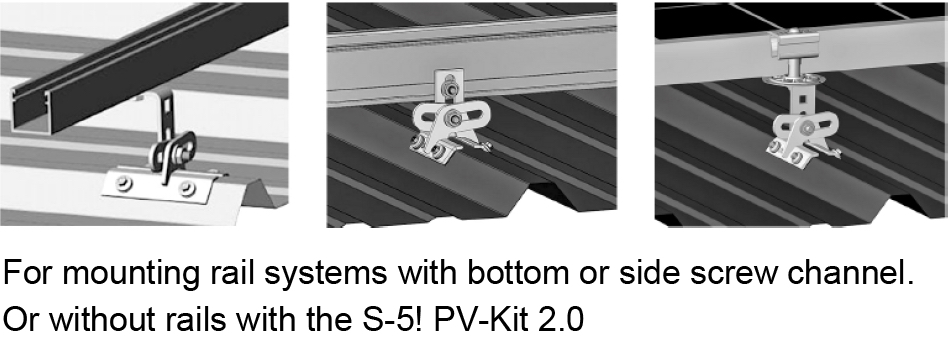

Various Attachment Solutions:

- Fixing of rails in many options

- Direct mounting of PV-modules with the S-5!-PV-Kit

- Mounting of roofwalk solutions, cable trays, etc.

(Unsuitable for snow retention and fall protection applications!)

Installation Instructions:

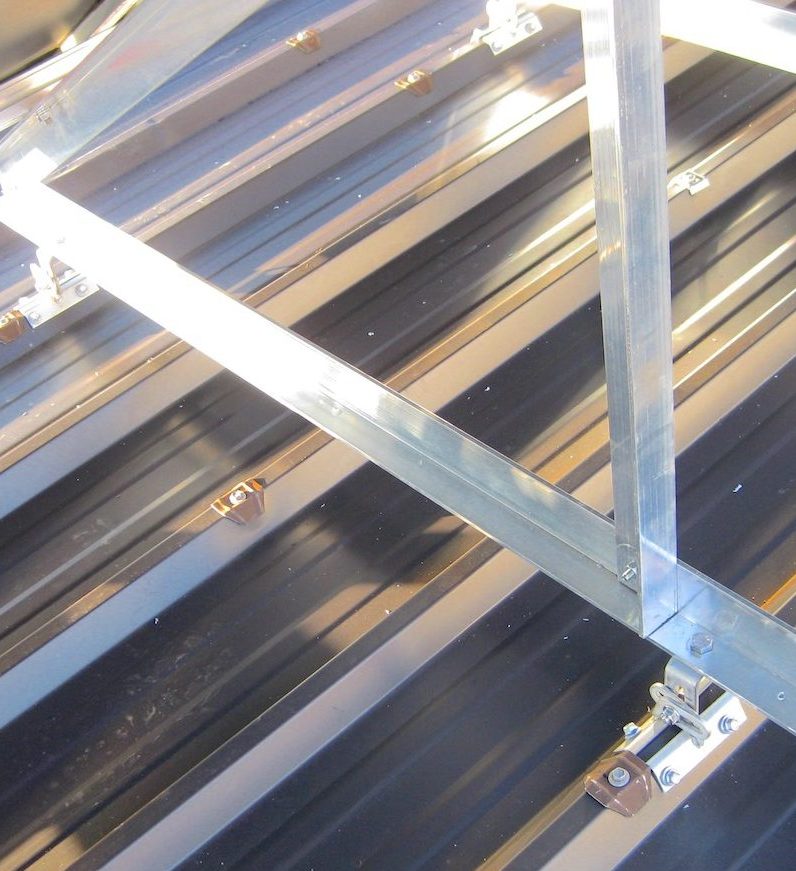

The Multi-Trapezoidal Bracket MTH is mounted directly onto the crown of the panel, straddling the profile. No surface preparation is necessary; simply wipe away excess oil and debris, align, and apply. Secure through its pre-punched holes, using the approved Hexagon Bi-Metal drilling screws with sealing washer. To ensure brackets are installed in a straight line, install a single Multi-Trapezoidal Bracket MTH each end of the roof at a measured, consistent distance from the bottom edge of the roof. Use a string line between the two brackets. Mount the remaining Multi-Trapezoidal Bracket MTH along the string line, directly into the sheeting of the trapezoidal rib of the roof.

RoofTech GmbH recommend that the planned installation, PV system, etc. should be verified by a qualified professional who is responsible for the snow and wind loads, the additional loads from the installations attached to the clamps, the statics and assembly as well as the planning and construction of and on metal roofs. For dimensioning, installation and application, the information and regulations according to the building authority approval by the DIBt No. Z-14.4.706 must be observed. During assembly, suitable tools with torque control must be used (the use of impact screwdrivers is not permitted).

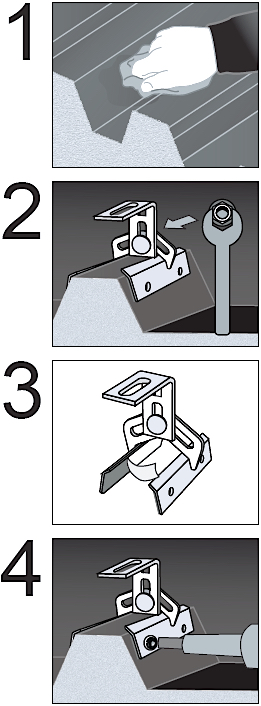

To install the Multi-Trapezoidal Bracket MTH:

-

Determine the location of assembly. The only surface preparation necessary is to simply wipe away excess oil and dirt from panel surface.

-

To create the appropriate fit, place Multi-Trapezoidal Bracket MTH onto the panel rib and tighten the hinge bolt to secure the bracket’s proper position (you will use a tool to tighten the hinge bolt to the specified torque at the end of Step 4). Note that the slotted L-flange should be oriented on the long side of the Multi-Trapezoidal Bracket MTH base.

-

Next, align carefully, and apply in the proper orientation. While the Multi-Trapezoidal Bracket MTH is reversible, when installing multiple brackets, be sure that brackets on the same row have the same orientation, i.e. the longer side of the bases should face the same direction. Do not remove the EPDM sealant as this is for weather-proofing.

-

Secure the Multi-Trapezoidal Bracket MTH directly into the crown of the roof profile by screwing the provided self-tapping stainless steel screws through the pre-punched holes of the Multi-Trapezoidal Bracket MTH, alternating from one side of the bracket to the other, and back again. Be sure to use all four pre-punched hole locations to achieve tested holding strength. Be careful not to overtighten the screws; slight compression extrusion of rubber around the washer is a good visual check. If a fastener has been stripped, it is important to remove the fastener and replace it with a waterproof bulb rivet or larger diameter fastener. To avoid stripping, use screw gun with depth sensing nose piece or adjustable torque clutch.

-

Lastly, hold the slotted L-flange firmly in place and tighten the hinge bolt/nut connection with a tongue moment of 20 Nm in each case.

The Multi-Trapezoidal Bracket MTH is now ready to install other ancillaries, such as rails and the S-5-PV Kit. When used in conjunction with the S-5-PV Kit, an extra M8-nut is necessary to secure Multi-Trapezoidal Bracket MTH’s slotted L-flange to the universal PV stud and mounting disk .

Please note:

the Multi-Trapezoidal Bracket MTH is unsuitable for snow retention and fall protection applications!

General Notes:

During installation and use, the information and regulations in accordance with the DIBt approval Z-14.4.706 must be observed. 4 stainless steel drilling screws with a thread diameter of at least 6 mm and a sealing washer of at least 14 mm are required for fastening in accordance with DIBt approval Z-14.1-4.706 or Z-14.1-537 can be used. Suitable tools with torque control must be used.

The planer, user and/or installer of these parts is responsible for all necessary engineering and design to ensure the Multi-Trapezoidal Bracket MTH has been properly spaced and configured. Responsible for the stability of a building structure is the building owner or the owner of the installation. The installer is responsible not only for the application and the installed system, but also for the roof on which the system is installed. Anyone who installs a system on an existing roof without having checked the stability beforehand violates existing law. If he is not able to assess the load-bearing capacity himself, he must obtain a static calculation from a specialist. On request, we will be happy to send you the specifications for design and dimensioning from the building approval.

Any loads imposed on the fixing products will be transferred to the panels. Panel seams must have sufficient flexural strength to carry these loads. Panels must also be adequately attached to the building structure, and the structure must be sufficient to carry these loads. The makers and RoofTech make no representations with respect to these variables. It is the responsibility of the user to verify this information, or seek assistance from a qualified design or structural professional, if necessary.

PLEASE USE THE PRODUCTS RESPONSIBLY! Panels must be adequately attached to building structure to resist these loads. For critical installations, inquire for specific test data of ultimate tensile load on specific panel materials and seam types. When tabled values are used, screw tensions should be verified and factors of safety should be used as appropriate. The manufacturer and RoofTech expresses no opinions as to the suitability of the products for any specific application or project condition.

The Multi-Trapezoidal Bracket MTH is unsuitable for snow retention and fall protection applications!

The respective installation instructions must always be observed. The user and/or installer bears also the responsibility not only for the professional installation, but also for the roof on which he is mounted. The user and/or installer must always clarify in advance the application possibilities and application of our products in connection with the other used materials and products at the single project.

It must be ensured by the planner and the specialist company responsible for the installation that the planning and installation are carried out strictly in accordance with the national and site-specific building regulations, occupational safety and accident prevention regulations, standards and environmental protection regulations.

RoofTech GmbH recommend that the planned installation, PV system, etc. should be verified by a qualified professional who is responsible for the snow and wind loads, the additional loads from the installations attached to the clamps, the statics and assembly as well as the planning and construction of and on metal roofs. The responsibility for the assembly and the applications is in principle not accepted from the producer and RoofTech GmbH.

The Installation instructions and more information to download under “Information” or send us an email for your request.

We assume no liability for errors on our website and in our documents. Pictures and drawings in our documents and webpages serve to clarify individual detail designs and are only recommendations. They can represent development stages, which are not available in such a way. The contents, logos, photos and graphics may only be used or passed on after consultation with RoofTech GmbH. The content and works provided on these Web pages are governed by the copyright laws of Germany. Duplication, processing, distribution, or any form of commercialization of such material beyond the scope of the copyright law shall require the prior written consent of its respective author or creator.

The business relationship is subject to German law, excluding the UN Convention on Contracts for the International Sale of Goods (CISG). Our General Terms and Conditions of Business (GTC) apply, which we will be happy to provide you with at any time (direct link to our RoofTech GTC). The linking of external websites to the RoofTech website is only permitted with the consent of RoofTech GmbH and if no rights of RoofTech GmbH are violated.

No liability for printing errors. Technical changes subject to modification.

© Copyright RoofTech GmbH, 7-2020. All rights reserved.

Peter Strobel

Peter Strobel